This is an exciting time. Cutting-edge technology enables us to zoom in

on individual atoms and take pictures and measurements. Theoretical

models and computer simulations that describe how atoms interact on

different scales are becoming more powerful. These tools are teaching us

more and more about the complicated forces at work inside of materials.

One of the ultimate goals of this work is to be able to create materials by design—to decide upon the properties you want in a material for a specific application and then build it atom-by-atom or molecule-by-molecule. We aren’t there yet, but we are on our way.

This week, a paper in Physical Reviews Letters reveals a new design technique that scientists can use to reduce the flow of heat through a material. This could be particularly useful for managing heat in the electronics that control our computer and communications systems.

You’ve probably noticed that phones, laptops, chargers, and other

electronic devices often get hot during use. Heat and electricity are

both types of energy. The heat given off by a laptop is wasted

energy—it’s a byproduct of the electricity traveling through the

circuits in your computer. All of this wasted energy adds up, so

anything we can do to prevent it from happening or to turn the heat into

useable energy is a good thing.

Thermoelectric materials have the ability to turn a temperature difference (hence “thermo”) into electricity, or vice versa. Actually all materials have some thermoelectric effect, but often the effect isn’t very big. Materials that have a big thermoelectric effect can be used to generate electricity from heat and to keep things cool. They enable more efficient electronics, helping to reduce the amount of energy we use.

While he was a PhD student at École Centrale Paris under Sebastian Volz, Shiyun Xiong started working on a project related to thermoelectrics that turn waste heat into electricity. He used a computer program to explore structures, or ways of arranging atoms, that don’t let very much heat through. During this process, he was surprised to see that one of the structures stopped significantly more heat than anyone expected—and no one knew why.

When scientists want to reduce the amount of heat that can pass through a material, they usually design it to optimize a specific scattering process that blocks heat. However, this scattering process did not explain the results that Xiong and his advisor saw.

After earning his PhD and moving to Davide Donadio’s group at the Max Planck Institute for Polymer Research, Xiong dove deeper into this mystery. It took another eight months of hard work, but eventually Xiong and colleagues at Ecole Centrale Paris and the Max-Planck Institute together developed a pretty clear idea of what was happening inside this structure.

The particular structure Xiong was exploring is a long, thin nanowire with “branches” coming out from the sides. It turns out that these branches can produce resonances that slow down the movement of heat. This is a completely different process than the scattering effect usually tasked with reducing the flow of heat. In the paper, Xiong and his coauthors explain how this works and show that these two processes—resonances and scattering—complement each other. By designing materials that optimize both processes, you can reduce the flow of heat significantly more than either process does alone and break the conventional lower limit of heat transfer, called the amorphous limit.

You can think about it like this. Imagine that heat is carried through a material by two different kinds of runners: slow-and-steady racers and sprinters. One process, scattering, blocks the sprinters. The other, resonances, slows down the slow-and-steady group. This two-pronged approach provides a promising new model for scientists designing thermoelectric materials.

-Kendra Redmond

One of the ultimate goals of this work is to be able to create materials by design—to decide upon the properties you want in a material for a specific application and then build it atom-by-atom or molecule-by-molecule. We aren’t there yet, but we are on our way.

This week, a paper in Physical Reviews Letters reveals a new design technique that scientists can use to reduce the flow of heat through a material. This could be particularly useful for managing heat in the electronics that control our computer and communications systems.

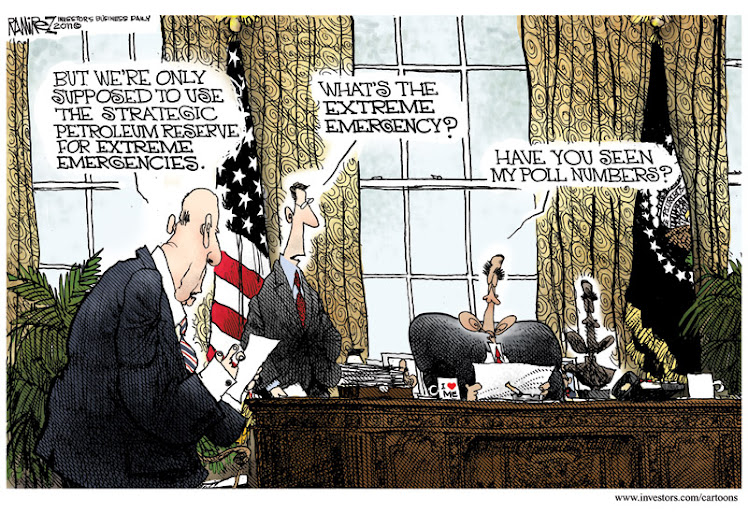

| When heat from an electronic device isn't properly dealt with, things can get hairy. |

Thermoelectric materials have the ability to turn a temperature difference (hence “thermo”) into electricity, or vice versa. Actually all materials have some thermoelectric effect, but often the effect isn’t very big. Materials that have a big thermoelectric effect can be used to generate electricity from heat and to keep things cool. They enable more efficient electronics, helping to reduce the amount of energy we use.

While he was a PhD student at École Centrale Paris under Sebastian Volz, Shiyun Xiong started working on a project related to thermoelectrics that turn waste heat into electricity. He used a computer program to explore structures, or ways of arranging atoms, that don’t let very much heat through. During this process, he was surprised to see that one of the structures stopped significantly more heat than anyone expected—and no one knew why.

When scientists want to reduce the amount of heat that can pass through a material, they usually design it to optimize a specific scattering process that blocks heat. However, this scattering process did not explain the results that Xiong and his advisor saw.

After earning his PhD and moving to Davide Donadio’s group at the Max Planck Institute for Polymer Research, Xiong dove deeper into this mystery. It took another eight months of hard work, but eventually Xiong and colleagues at Ecole Centrale Paris and the Max-Planck Institute together developed a pretty clear idea of what was happening inside this structure.

The particular structure Xiong was exploring is a long, thin nanowire with “branches” coming out from the sides. It turns out that these branches can produce resonances that slow down the movement of heat. This is a completely different process than the scattering effect usually tasked with reducing the flow of heat. In the paper, Xiong and his coauthors explain how this works and show that these two processes—resonances and scattering—complement each other. By designing materials that optimize both processes, you can reduce the flow of heat significantly more than either process does alone and break the conventional lower limit of heat transfer, called the amorphous limit.

You can think about it like this. Imagine that heat is carried through a material by two different kinds of runners: slow-and-steady racers and sprinters. One process, scattering, blocks the sprinters. The other, resonances, slows down the slow-and-steady group. This two-pronged approach provides a promising new model for scientists designing thermoelectric materials.

-Kendra Redmond